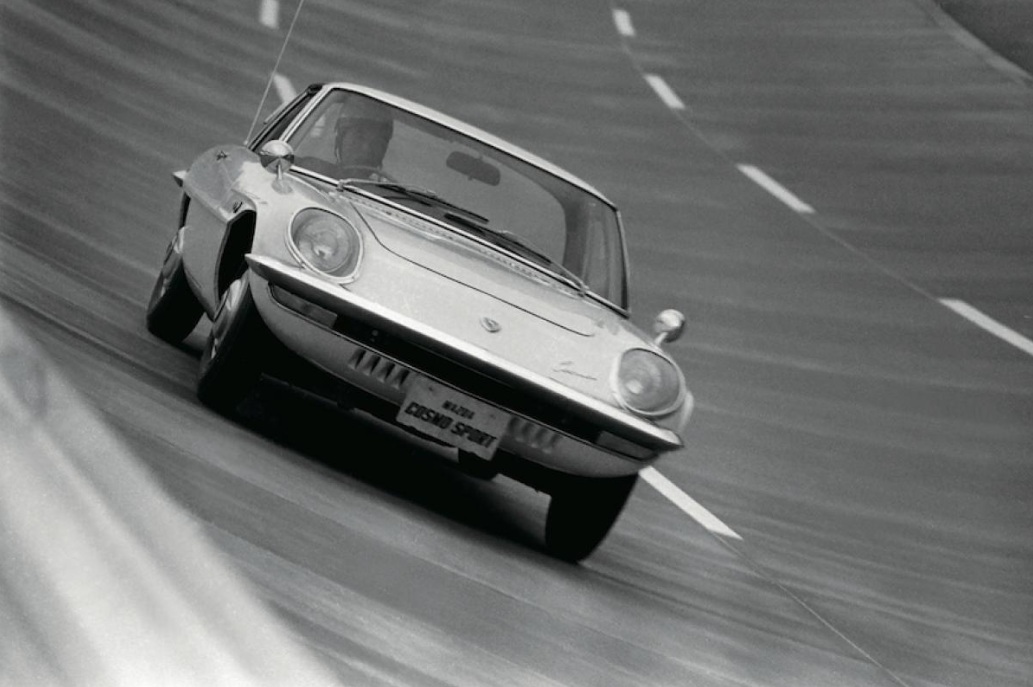

Mazda Cosmo Sport (1967)

Publication: Motor Fan

Format: Road Test

Date: August 1967

Author: Kenichi Yamamoto, Mamoru Watanabe, Osamu Hirao, Masashi Kondo, Kazuo Kumabe, Atsushi Watari, Kenji Higuchi, Kazuo Takada, Akio Miyamoto, Yasuhisa Minagawa, Saburo Araki, Yasuhei Oguchi, Mineo Yamamoto, Toshihide Hirata, Masataka Matsui, Minoru Onda, Motor Fan Editorial Staff (uncredited)

Unique Rotary Engine Completed

Magazine: First, please tell us about the difficulties you faced in completing the rotary engine, which is the heart of the Cosmo.

Yamamoto: It has been about six years since Toyo Kogyo started building rotary engines. During that time, the biggest problem was durability. This was the point we put the most effort into during the research and development stage. After we had a handle on the durability, we solved the problems of optimizing it for use as an automobile engine, such as increasing flexibility to improve performance at low speeds and torque, and we were able to reach a point where we were absolutely confident, which is why we are now releasing it.

The biggest problem directly related to durability was the chatter marks that occur on the inner surface of the trochoid, that is, corrugated wear. Figuring out how to solve this was the most important issue in our research. We had no idea why it occurred, so we had no way of dealing with it. So we started by addressing the basic problem of why corrugated wear occurs, and conducted thorough research and experiments. In the end, this steady, methodological approach opened the way to solving the chatter marks.

Magazine: The Cosmo engine seems to be quite different from the single rotor engine of the NSU Wankel Spyder.

Yamamoto: The theory is the same as the NSU engine, but structurally it is very different. The Spyder engine was very much focused on high engine speed and high power, but Toyo Kogyo made an effort to make the engine flexible enough to be used over a wide range of revolutions. To achieve this, the intake method is very different from NSU’s. As you know, it uses a side port type that takes in air at a right angle to the housing, and Toyo Kogyo was the first to put two plugs on one housing. Of course, the use of two rotors is the biggest difference.

Watanabe: My point of view is a little different, and I would like to emphasize that the development processes of Toyo Kogyo and NSU were very different. Toyo Kogyo researched various problems starting from the basics, which seems difficult, but in the end I think it can be said that it hastened the solutions.

Yamamoto: We also did a lot of research into single rotor engines at first, but partway through we realized that two rotors would be easier to drive as an automobile engine, so we focused our efforts on developing two rotor engines. So we couldn’t just bring in NSU’s single rotor technology as it was… That’s where things diverged and became quite different.

Hirao: It’s important to build up from the basics. Even if an individual genius comes up with an inspired idea, it’s difficult to make it a reality if there isn’t any enthusiasm in the subsequent research resolving “chatter marks.”

Kondo: What wavelength does the chatter mark have, and what is its cause?

Yamamoto: Chatter marks vary depending on the engine’s operating conditions, but in our experiments, a vibration phenomenon of about 17,000 cps occurs, which is a kind of frictional vibration that causes it, and various factors are involved, such as the friction characteristics between the sliding surface and the seal, and the vibration characteristics of the seal itself.

Kumabe: The inner surface of the trochoid is plated, but can the plating come off due to these chatter marks?

Yamamoto: If this progresses, yes, the plating will eventually come off. This will prevent the engine from turning and will lead to its destruction.

Kumabe: How long does it take for it to occur?

Yamamoto: This also varies depending on the operating conditions, but it is most likely to occur at high engine speed, and with the throttle fully open, the symptoms initially appeared after about 100 hours. So we researched various seals, and when we drilled small holes in them (we called this the “cross-hollow” type), we found that the seal life was about three to five times longer. Finally, we came up with a seal that doesn’t use metal, but is made of carbon. With this, chatter marks don’t occur at all.

Watari: What frequency is the 17,000cps that you mentioned earlier?

Yamamoto: This is the bending frequency of the apex seal.

Kumabe: I’ve heard that the problem of plug fouling was also serious, so how did you solve this?

Yamamoto: At first we used a single plug, but it was quite difficult to start the engine at low speeds. If you pulled the choke incorrectly, the plug would get wet and the engine wouldn’t start. Of course, we changed the properties of the plug and the shape of the hole near the plug in various ways, but we found that the biggest problem was the position of the plug. The current engine uses two plugs, and one of them is attached where it is very resistant to getting wet. The other is good in terms of performance, and these two combine to cover the performance requirements of an automobile engine. This way, there is no need to worry about plug fouling or lubrication.

Higuchi: So now, if the engine fails to start on the first try, that no longer means it won’t start again?

Yamamoto: That’s right.

Kumabe: What is the lifespan of each plug?

Yamamoto: We conducted road testing on this, and it was about 10,000 to 12,000 km.

Kumabe: I don’t think there will be any problems with it at this time of year, but how does it start in the cold winter?

Yamamoto: When it’s cold, it’s easy for a lot of raw fuel to get in, but we ensure the plugs don’t get wet, so there’s no problem.

Takada: In a cold weather test conducted in Hokkaido in 1964, we deliberately wet the plugs with fuel before installing them to test the power of the lower parts of the two plugs, but they worked perfectly fine. In the end, as long as the mixture ratio was normal, even if they were wet, they dried quickly and ignited normally. After all, if the mixture ratio is off, even a reciprocating engine won’t start…

Hirao: Another thing we’re worried about is lubrication. Can you tell us about that?

Yamamoto: There are two types of lubrication for a rotary engine: the rotor and the inner surface of the trochoid, and the lubrication of the side seal. As for the rotor, the seal itself vibrates a lot, so it is natural to think that the oil film will break, and I think the carbon seal was successful in this respect as well. Carbon itself has a lubricating effect. However, from the perspective of a gas seal, lubricant is also necessary.

Therefore, the idea of lubrication of the trochoid surface is not in the sense of a wear-resistant material or anti-friction agent, but rather that lubrication is necessary as a gas seal agent. There are various methods for this, but the idea is to control and mix oil into the intake gas.

As for the side seal, the lubricating oil that cools the inside of the rotor splashes off the rotor and falls to the bottom when the rotor is cooled, and in the process, it splashes out on top of the side housing. And there is an oil seal inside the side seal, which controls the scattered oil. I think this is enough to provide lubrication within a practical range.

Gear Installation After Extensive Research

Miyamoto: What kind of fuel does it use?

Yamamoto: Regular gasoline is fine.

Hirao: Another thing I’m concerned about is the gear in the center of the trochoid. Are there any technical problems with that gear?

Yamamoto: Actually, this was one of the things we struggled with. In the beginning, this gear broke a lot. It would break at a certain rpm. It wasn’t just when the throttle was fully open, but it was related to the rpm. We started from the basics, and analyzed the gear load. We found that the combustion pressure was one of the exciting forces. So we changed the shape of the combustion chamber, the position of the plug, the moment of inertia of the rotor, the method of attaching the gear, and so on, and now the gear breakages have completely stopped.

Hirao: So it was from a kind of torsional vibration of the rotor, then.

Higuchi: It seems that the oil consumption is very small compared to the NSU. The NSU requires more than four liters of oil for a single rotor, but the Cosmo requires less.

Yamamoto: I don’t know about the current NSU engine, but in the beginning, the Cosmo’s also consumed a lot of oil, and white smoke was coming out of the exhaust pipe, but after developing the oil seal, we were able to bring it to a practical level.

After that, since oil is also used as a coolant, we were worried about oil contamination. We also did research on whether the oil would be contaminated by blow-by from the gas seal. However, our engine has an advantage in terms of blow-by gas. That is, the side port type intake port always has a chance to be located between the side seal and the oil seal. That way, the wet gas from the side seal can be recirculated, so I think that the oil contamination is very low.

Higuchi: When I read the manual, it says to use a certain specified oil, but is it something special?

Watanabe: No, this specification means that we want you to use the original oil, and of course normal oil is fine.

Fuel Economy is 14.3km/l

Hirao: What is the oil consumption rate?

Yamamoto: When driving continuously on the highway, it’s about 3,000km per liter, but in a mix of medium-, high- and low-speed driving, it’s about 2,000km.

Hirao: Well, that’s a normal amount. What about fuel economy?

Yamamoto: At a constant speed of 50km/h, it’s 14.3km/l. The average fuel economy during varied driving is 13.5km/l at an average speed of 53km/h.

Kondo: How much is that in g/ps/h?

Yamamoto: It’s 235g/ps/h at full throttle.

Hirao: If you think of it as having a 110ps engine, 14.3km/l is a good figure. 110ps is what you’d expect from a 2-liter sedan type.

Higuchi: If you think of it simply as one type of gasoline engine, it’s said that the shape of the combustion chamber should be as close to spherical as possible. However, the Wankel combustion chamber has a flat shape, which makes knocking a concern. What do you think about that?

Yamamoto: Certainly, in terms of flame propagation time, a spherical shape is best, and one would think that this Wankel shape would cause knocking. However, a characteristic of the Wankel is that compression turbulence is very intense in the direction of rotation. This shortens the time for combustion propagation, and seems to make it resistant to knocking.

Compact body compared to power

Magazine: We’ve talked quite a bit about the Wankel engine itself, but let’s get back to the Cosmo Sport and talk about the process that led to the development of the Cosmo.

Minagawa: The basic concept behind the Cosmo is to make the most of the rotary engine’s characteristics. The rotary has many advantages, but the main ones are that it is compact compared to its power, and has very good high-speed performance. Of course, it is natural to also place importance on low-speed performance in a passenger car, and it is also important to be able to compete with reciprocating engines in terms of vibration, noise, and durability. So, for our first rotary car, we aimed for a sports coupe from the beginning. At first, we were thinking of a pure sports car for high-speed long-distance touring, but as a practical consideration, it was also necessary to have sufficient performance even at low speeds. As advertised, the Cosmo can accelerate from 25km/h in top gear, so it has grown into a practical car that can actually be driven around town in top gear.

As for the style of the car, it was a completely Japanese design that made use of the free ideas of the young designers in the company, starting from the idea that “because the rotary engine is a new technology, the car itself should be as new as possible, and we want a style that breaks through conventional ideas.” We are currently planning a sedan-type car as the second model in the Cosmo series. This will a car that is more aimed at the popular mass market, and we are also thinking about a body style that is suitable for the rotary engine.

Watanabe: To be specific, the character of the Cosmo has gradually changed in line with the development of the rotary engine itself. At first, it was just a sports car, so the gearbox was a 5-speed, the steering was sharp, the springs were stiff, and it was primarily a car for driving on a circuit. However, as it was developed further, and a very flat performance curve was achieved, we decided to make the character of this car more like a touring car.

For example, we changed the gearbox to four-speed, lowered the steering rigidity, and made the suspension tuning closer to that of a sedan.

The Characteristics of the Rotary Engine

Hirao: There are some things about rotary engines that reciprocating engines cannot imitate. For example, the external shape is compact, which allows the bonnet line to be much lower. The size of a 110ps reciprocating engine is incomparable to this, so a reciprocating engine car cannot imitate this car’s styling. Another thing is that it does not have a valve mechanism, which is the most troublesome part of four-stroke engines. If you make full use of this point, I think it will result in a very wide range of rotation speeds. It seems that the recommended rev limit is currently kept to 7000rpm, but I think this is very conservative. If you were to increase the limit to about twice this much, the car would be able to reach 100km/h in first gear. This is also something that reciprocating engines cannot imitate. Of course, the torque would drop significantly, but that is fine. Being able to pull cleanly at low speeds means you can significantly shorten the standing quarter-mile time, which I think is extremely advantageous.

In that case, a transmission with fewer gears would be more than sufficient; one with three speeds, or even two… (laughs).

Yamamoto: The body style that takes advantage of the rotary engine’s characteristics, and the wide range of revolutions, are certainly two important points that we will continue to focus on in the future. You pointed out that 7000rpm is a little low for a rotary engine, and you’re absolutely right, but because this is the first car we’re releasing, we’re being extremely careful about durability. In the future, we’ll probably move in the direction of increasing the revolutions to bring out the true strengths of the rotary. Of course, we’ll keep the current low-speed performance as it is.

Watanabe: The Cosmo has achieved a fairly effective reduction in the bonnet line. There are cars whose overall height is equally low, but with a reciprocating engine, the bonnet is so high that the windshield is quite narrow, resulting in poor visibility.

Yamamoto (Mineo): On that point, when you open the bonnet, the engine is very small, but the auxiliary equipment around it is the same size as in a conventional car, so the engine bay is still quite crowded. That’s a shame.

Yamamoto: You’re right about that. I think we need to continue researching compactness, including accessories, in the future.

Hirao: In that sense, rotary-specific accessories are a necessity.

The Rear Suspension is De Dion Type

Miyamoto: The two-year, 50,000 km warranty period is impressive. Speaking of experimental powerplants, it seems that the gas turbine cars made by Rover and Chrysler have disappeared, so what are the relative advantages and disadvantages of the rotary and gas turbines?

Yamamoto: Gas turbines have their merits, but I think they are different in terms of application. In my opinion, the gas turbines currently being developed are suitable for large vehicles, whereas rotary or reciprocating engines are more suitable for medium and small vehicles.

Watari: Why did you decide to use the De Dion type for the rear suspension?

Watanabe: We chose this because we wanted to lower the vehicle height and lower the center of gravity, and the central tunnel could be made too high, so we thought the De Dion type was the better choice than a conventional suspension.

Watari: Did you have any problems incorporating the De Dion type?

Watanabe: As expected, we had trouble with the noise at first, because the differential is fixed to the body. However, this has now been largely resolved. The biggest problem was the various impact noises coming from around the De Dion mount, so we made changes to the mount design and moved the mounting location to eliminate them. Also, noise from the spline shafts is a common problem, but we solved this by using ball splines. We think it’s come a long way for a car of its class.

Higuchi: During today’s test drive, I tried driving it on the rough road course in Miyoshi, and if the car’s character has become more touring-like, I’d like to take it out to rougher roads in the suburbs, on hill climbs, and cross-country.

Watanabe: The ground clearance is about 140 to 145 mm at the De Dion tube, which is much higher than most American cars.

Quiet For a Sports Car

Magazine: Now, Professor Watari will tell us about the results of the noise tests.

Watari: First, I will read out the data. The noise inside the car, was measured on the A scale, was 62 hones at 40km/h, 68 hones at 60km/h, 73 hones at 80km/h, 74 hones at 100km/h, 77 hones at 120km/h, and 78 hones at 130km/h. The conditions of the test course were different from those in Murayama, so we cannot directly compare the data with other Motor Fan tests, but in general, it is not particularly quiet by passenger car standards, but is fairly quiet for a sports car. When I actually drove it, I got the impression that it was a relatively quiet car. However, when I let the speed drop down to about 25km/h in top gear, I heard a loud rustling sound.

Watanabe: Still, I think it is on the low side in terms of driveline wind-up and vibration… As for the sound level, if we install this engine in a sedan next time, we plan to muffle the exhaust even more.

Watari: As for the external noise level, I can’t say for sure because the data can’t be compared directly, but I think it’s a little on the high side.

Araki: Compared to other sports cars, however, we think it’s on the low side.

Magazine: What about the suspension’s vibration frequency?

Watari: The unsprung vibration at the front is 1.8 cps, and the rear is 1.85 cps, which corresponds to about 100 vibrations per minute. The unsprung vibration frequency is about 12 cps, which is a little on the hard side, but it’s a sports car, so that’s to be expected. In reality, it feels softer than these numbers suggest.

Magazine: Next, please announce the results of the power performance test conducted today at the Miyoshi test course.

Oguchi: We measured standing-start acceleration times with only the driver aboard and also with two people on board. With only the driver, the times were 4.2 seconds for 0-50m, 6.5 seconds for 0-100m, 10.1 seconds for 0-200m, and 15.9 seconds to go from 0-400m. This time, we were also able to run up to 1000m, and 0-1000m took 29.8 seconds. Next, with two passengers, the times were 4.3 seconds for 0-50m, 6.8 seconds for 0-100m, 10.3 seconds for 0-200m, and 16.3 seconds for 0-400m. These figures are exactly the same as those in the catalog.

Looking at the acceleration in terms of time to speed, with one passenger, it reached 60km/h in 3.2 seconds, 100km/h in 8.1 seconds, and 140km/h in 16.7 seconds. With two passengers on board, it reached 60km/h in 3.5 seconds, 100km/h in 8.8 seconds, and 140km/h in 18.0 seconds.

Next, for overtaking acceleration, starting from 40km/h in top gear, it took 6.8 seconds to 60km/h and 19.8 seconds to 100km/h. From 30km/h in third gear, it took 6.2 seconds to reach 60km/h, 14.2 seconds to reach 100km/h, and 23.8 seconds to reach 140km/h.

Today’s test conditions were not good, with occasional light rain. It seems that the car had some wheelspin at the start of each run and lost about 0.3 seconds.

Amazing High Speed Performance

Magazine: Have we ever tested a car that could achieve 0-400m in 15.9 seconds?

Oguchi: No car has been this fast in our testing yet. My impression when I drove the car was that the g forces during standing-start acceleration runs started off strong, and remained strong. Good acceleration is one of the rotary’s distinctive features.

Magazine: Also, this was a larger test course, so we were able to test the top speed.

Oguchi: When we talk about top speed, we don’t just mean the top speed that can be achieved instantaneously. We did four laps around the Miyoshi test course (one lap is 4.3km), and calculated the average speed per lap from the lap times, and the result was a little over 200km/h.

Yamamoto (Mineo): I’d like to ask something about this. The top speed listed in the catalog for this car is 185km/h, but when I test drove it, the needle went over 200km/h many times. Does the catalog value leave that much leeway intentionally?

Minagawa: This catalog top speed is not the instantaneous top speed, but what we call the guaranteed top speed. For example, in the case of the Familia, the guaranteed speed is 115km/h, which means you could theoretically expect it to maintain that speed and circle the earth once or twice. The Cosmo is the same; it can run continuously at 185km/h or more, and can easily reach 200km/h momentarily. However, in consideration of maintenance and engine life, the speed in top gear at the 7000rpm limit is about 185km/h, which makes it the maximum guaranteed speed we can take full responsibility for.

Besides that, there is also the issue of tires, and it may be dangerous to reach 200km/h continuously with the current low-profile tires, so we announced a speed of 185km/h for the time being.

Hirao: If there are any issues with the tires, it would be better to make that clear. For example, you could say that with these tires you should limit your speed to 185km/h, or that radial tires should be used for speeds above that. In Japan, there are still no roads on which you can drive continuously at 200km/h, but in Europe, radial tires may be necessary.

Watanabe: The current tires are low-profile H-type bias-ply, but this doesn’t necessarily mean we can’t guarantee a speed of 200km/h. However, if you want to be absolutely sure, you’ll need radial tires.

Slight Understeer

Magazine: Let’s move on to the topic of maneuverability and stability.

Kondo: Our methodology was different this time in that Toyo Kogyo published the test data in advance, so we conducted tests mainly to evaluate the feeling while using Toyo Kogyo’s data as a reference. First, we tested oversteer and understeer. The Miyoshi skid pad area is large, with a diameter of 100m, so we conducted three types of tests, our usual turning test in a circle with a radius of 15m, plus turning tests in a slightly larger radius. First, we started gently in a 15m radius circle, shifted to second gear, and accelerated further. At first there was slight understeer, then the balance became neutral around 40km/h to 50km/h, and from that point on we felt a decrease in steering force. We accelerated to 60km/h, and at that point, it started to oversteer.

When we widened the turning radius to 30m and accelerated in the same way, slight understeer continued until we reached 60km/h. Finally, we widened the turning radius to 40m, and at 50km/h, the car was experiencing a slight understeer that made it seem as if it was going to start pushing wide, but it had not yet reached the point of reducing steering force. Toyo Kogyo’s in-house data is based on gentle acceleration in third gear, and shows that the car maintained slight understeer until the end. The lateral acceleration reached 0.77g in this data, but that seems to be a little different from the actual feeling.

Next, the comparison between R/R₀ and V² (m²/s²) is one of the key criteria for judging the degree of understeer, and when V² is 100m²/s², the general tendency is that sports cars are around 1.3 and sedans are around 1.5. In the graph provided by Toyo Kogyo, the Cosmo falls exactly on that line. In addition, the roll rate is about 2.3° at a lateral acceleration of about 0.5g. This is also the most natural roll rate for a sports car.

Next, the force required to turn the steering wheel when stationary is shown as being about 10kg for a 360° turn to the left, and 12kg to the right, but in reality, it felt a little heavier. The figure-eight test, which measures steering force when cornering at low speeds, is about 5kg at a lateral acceleration of 0.25g. The steering force at high speeds was measured in a slalom test, and was 2kg at a maximum lateral acceleration of 0.25g, which again seems to be a little stronger in reality. Overall, I think the values should be a little larger than what is shown in the manufacturer data.

The results of the free-release directional stability test were measured at Miyoshi’s 1.7km straight course, and the published data only includes speeds up to 160km/h, but we accelerated on the curved section and tested it on the straight section up to 180km/h. In either case, the convergence worsens as the speed increases, but even at 180km/h it converges to 0; that is, to a straight line. I think this is an especially desirable trait for high-speed vehicles.

Parking Brake Position is an Issue

Magazine: Next, let’s move on to the topic of brakes and weight.

Yamamoto (Mineo): The brake force is generally a little higher than the average for domestically manufactured cars. Because the front brakes are disc type, you can use them safely even from high speeds, but how should I put it, the pedal feels like it stretches under hard braking, and the effort is heavy. Is it possible to install a servo booster on a car of this size?

Watanabe: There was a lot of discussion within the company about whether to use a servo. However, we decided not to install one because we felt that this level of brake force was under the limit of what could be achieved without a servo. If this were a sedan, we would naturally install a servo; for example, the recently released Luce SS has one. It is said that a servo is necessary when the pedal effort reaches about 35 kg, but in the Cosmo, it’s around 30 kg…

Higuchi: It’s a matter of getting used to it. Your impression will vary greatly depending on the brakes in cars you have driven previously.

Kondo: I also felt that the brakes were a little heavy.

Higuchi: I think this would make things quite difficult if you were to go on a long-distance tour.

Yamamoto (Mineo): As for the parking brake, it has a sufficient ratchet effect and works well, but it’s very uncomfortable to pull it with any force in its current position…

Hirao: It’s definitely a little difficult. Even when you release the brake and the lever is all the way down, it still looks like the brake is partially applied…

Watanabe: The problem of the parking brake’s position was quite a headache. I actually wanted to put it on the right side of the transmission tunnel, but the width of the seat and other factors led to the current position. I also tried moving it forward and backward, but in the end I settled on the position it’s in now.

Higuchi: That’s right. I was thinking it could be placed by the driver’s knee on the right side of the tunnel instead, but then there’s the issue of seat height, and since the seat is low it would be difficult to use. I think it would be better to use a walking-stick type and place the handle closer to the floor, and pull it towards you to set the brake… We checked the relative position of the seat and the pedals, and it seems that the pedals are slightly offset to the right. Therefore, if the seat was moved to the right, we think that its position relative to the pedals and the parking brake lever position problem would both be solved at once.

Watanabe: The width of the seat is 480 mm, and it already uses up all the space to the inner door panel, so I think that’s a bit difficult. In fact, we would like the seat itself to be 500 mm, so we are considering what to do about this.

Yamamoto (Mineo): Next, in terms of the vehicle weight, the front-to-rear weight distribution is 46.5:53.5 when the car is empty, and 45.7:54.3 when fully loaded. Even though it is a normal FR layout, the car is somewhat rear-heavy, which is probably due to the light weight of the rotary engine, and this figure is actually very similar to that of a rear-engined car. The car weighs 962kg using the Motor Fan test method, which includes a spare tire, tools, and a full tank of gas, so it is about 22 kg heavier than the nominal weight of 940 kg. The gasoline tank has a capacity of 57 liters, which is large for this class.

Watanabe: We made the gasoline tank as large as possible to give it a longer range, in keeping with the nature of a touring car.

Generally good front and rear vision

Magazine: Now, please tell us the results of the visual field measurements.

Yamamoto (Mineo): On June 3rd, we took various photographs using a fisheye lens at Tokyo University of Agriculture and Technology, and measured the visual field. Hirata-kun will provide the details…

Hirata: We put a dummy driver in the seat, and placed the fisheye lens at the eyepoint. The height from the ground to the eyepoint is 980 mm when the seat is all the way forward, and 975 mm when it is all the way back. The distance from the lens to the windshield is 34cm with the seat all the way forward, and 50.8cm all the way back, with the seat slide travel being 168 mm. I was very surprised at how low the eyepoint was in this car. The height of 97-98 cm is about 20 mm lower than that of an ordinary sedan. The distance to the windshield is also closer, which helps to widen the field of view.

The resulting visible range through the windshield of 131° left-to-right with the seat fully forward, and 103° when it is pushed back. The vertical blind spots are 38° and 27°, respectively. The rear window is also very large, offering a wide field of vision, with blind spots from 68° to 90.5° left-to-right, and 22° to 26° up and down. The wiper’s horizontal wiping range is 110° to 81° left and right. The total dead angle in the horizontal plane, including the line of sight, is 117° (in front of the seat), or about 32.5%. If the seat is moved back, this is 80.5°, or 22.4%. If you look exactly 180° forward from your viewpoint, the dead angle is 38° to 23°. The blind spot to the right, including the triangular window frame and right front pillar, is 26° to 16°.

Expressing this in another way, in solid angles, the visible range is 1.49 to 1.31 steradians in front, and 1.19 to 0.72 steradians for just the front window, and the wiper’s wiping range is roughly 59% to 65% of the visible range of the front window. Both of these values are better than average for cars in the same class. However, the visible range of the rearview mirror is only 57% to 44% of the rear window, which is surprisingly small, partly because the rear window itself is large. I don’t think it’s a problem on flat roads, but I felt it was a bit inconvenient when I drove on the banking yesterday. I think the mirror needs to be a little larger, or the mounting position needs to be improved.

Wide Visibility is a Mazda Tradition

Yamamoto (Mineo): As Hirata-kun just explained, this car has very good visibility. Was any special consideration given to this from the beginning of the design?

Matsui: It has been a tradition for Toyo Kogyo’s cars to have large windows, and with this car, the goal was to make the window area as large as possible. In fact, the original plan didn’t even include a roof. Instead, it had something like an airplane canopy. However, this was thought to be a bit too extreme, so a small roof was added and the current style was created.

Watanabe: This is because Toyo Kogyo’s policy is not to make cars that make the driver feel like they are in a coffin, so we are always thinking about lowering the car height while making the window area as large as possible. The Luce is a good example of this.

Yamamoto (Mineo): Both the front and rear windows are very steeply inclined, so I wondered if the view out would look distorted from inside the car.

Watari: The bonnet is long and the viewpoint is low, so you see lots of blue sky in the view forward, but the drawback is that it’s difficult to see the ground…

Hirao: You may not be able to see the ground, but you can see people standing there. Anything over about 50cm above the ground is no problem.

Hirata: It’s not an official calculation, but judging from the photos, it seems that you can see the ground about 8 meters ahead of the bumper.

Magazine: Next, we would like to ask for the data on dimensions and control forces, which was done by the Higuchi Laboratory of the Tokyo University of Agriculture and Technology.

Onda: As others have mentioned, the first thing you notice about the styling is that the overall vehicle height is very low. However, when we measured the minimum ground clearance near the center of the differential, it was 140 mm. The catalog lists a ground clearance of 125mm, but that is measured from the lowest point of the front suspension members. However, the differential is the most important point for ground clearance in actual driving, so I would like the catalog to say 140mm as well.

Watanabe: This is an issue for the Ministry of Transport.

Forward and backward adjustable steering

Onda: As for the dimensions of the interior, I wore a helmet during the test drive yesterday, and the ceiling was a little cramped and I bumped my head getting in and out…. I measured the headroom and it was 855mm, which is a little low for a car of this class. However, it may be no problem without a helmet. Also, the steering can be adjusted for reach by 60mm, which is a major feature. If you combine this with the 168mm of seat travel, I think you can get a fairly spacious driving position. Also, this depends on the design policy, but up until now, manufacturers have tried to increase the rated passenger capacity by any means possible, but with this Cosmo, they have simply called it a two-seater. However, when I measured the interior, I felt that if they made some changes to the rear trunk and gas tank, they could actually create enough space for two children in the rear, and make it a so-called 2+2 type.

Even without going that far, it seems that the luggage space behind the seats could be made larger and more functional. As for my impression from the passenger seat, the driver’s seat has a footrest on the left side of the pedals, but the passenger seat has none, so I wished there was a toe board to put my feet on. There’s no grab handle, either, and it feels a little unsettling to be in the passenger seat of a car going 200km/h with nothing to hold on to.

Watanabe: Actually, we have already added a toe board.

Onda: With the three-point seat belt fully fastened, I could reach all the controls from the driver’s seat. As we discussed before, I wish the the position of the parking brake could be fixed somehow, but in terms of complaints, that’s about it. As an aside, I was amused to see that the name of the lever sticking out to the right of the steering column is written in the instruction manual as “Blinker and Dimmer and Wiper and Screen Washer Lever.” That’s certainly what it is, but I wish it had a more clever name.

Watanabe: That’s true. Maybe we should rename it to something like the “combination switch” (laughs).

Onda: Also, the car has a nice map lamp on the dashboard, but I didn’t see an overhead lamp… When you open the door, no lighting comes on at all. It seems to be pitch black at night.

Hirao: While we’re making requests, I think the instrument panel should have an oil pressure gauge.

Watanabe: We had installed one at first, but we removed it due to problems with the accuracy and reliability of the meter, and now it has a warning light instead. I think it serves its purpose.

Higuchi: The horn has two tones, and there is a switch to change between them, but why not put the horn buttons in two places, so you can press the one for the tone you want as needed? The horn is something you use in a hurry, so if you take the time to move the sound switch, it’s too late to use the horn anyway.

Watanabe: The idea is to switch between them for city and highway use…

Average Safety Check Score

Magazine: Professor Higuchi, what did you think about the safety?

Higuchi: Our safety evaluation is based on the American GSA standards, and we’ve created a safety checklist with a Japanese twist and my own ideas, and we give each category a score from 1 to 5 based on that list. Five points is a good example for other cars, one point is something that needs to be improved immediately, and three points is a good average. There are five main categories: body, interior, seating, and driver protection, and these are further divided into 30 sub-items, so the total score is 150 points. The problem is that we made this list for sedans, and we’re wondering whether it’s okay to use it for sports cars like the Cosmo, but we used it as-is this time. The result was 112 points out of a possible 150 points, which is 75 points out of a possible 100 points.

In terms of design details, the dual-circuit brake system, the padded all-black instrument panel, the adjustable steering column (which I think would help soften the shock somewhat in the event of a crash), and the laminated glass windshield all received good marks. Also, the interior door handles, window latches, and window cranks are rubberized or hidden behind the elbow rests, which I think contributes to occupant safety.

However, the bumper, which looks sharp at first glance, is a little higher than normal, which gives it a low score. In fact, it is a wrap-around type, meaning that it curves around all the way to the sides, which is safer for pedestrians. If the bumper had a slightly rounder rubber pad, it would be perfect. Overall, while the score is low in many other areas compared to recent sedans, I think that a sports car-like look and safety can go hand in hand, so I would like to see manufacturers put more effort put into this.

Also, this is more of an ergonomic matter, but the window cranks work in the opposite direction to those of a normal car. This is not a big deal once you get used to it, but it is a bit confusing at first.

Watanabe: Thank you… Most people do seem to turn the window cranks the wrong way at first. But in fact, if we installed them the other way around, the internal mechanism wouldn’t fit.

Easy Maintenance Even With a Rotary

Higuchi: Next, let’s take a look at maintenance. To be honest, since rotary engines are sophisticated mechanisms and there were considerable difficulties in their development, I thought that maintenance would be quite troublesome. But when I actually looked at the owner’s manual and listened to what people had to say, I was surprised to find that it was no different from, or even easier than, a reciprocating engine.

Specifically, you can leave the coolant system alone for two years or 40,000km, you change the oil at 1,000km and then don’t need to change for another 6,000km, and change the oil filter at 12,000km. For the average person, who drives about 14,000 to 15,000km a year, that means you only need to change the oil when the seasons change from hot and cold, and change the filter once a year. Furthermore, you only need to check the suspension every two years, every time the vehicle is inspected, which is actually easier than a normal reciprocating engine. Even better, you can use regular gasoline. However, when I read the manual, it says not to use the engine at less than 2000rpm. I think that means to downshift if the rotation speed drops below 2000rpm.

Takada: It just means that it’s easier to drive if you do so; it does not mean that the torque drops suddenly when the rotation speed drops below 2000rpm.

Higuchi: That is probably true, but there are misunderstandings about rotary engines and low rotation speeds, so I would like to see a clearer explanation, such as saying that there are no problems in practical use at less than 2000rpm, as long as you don’t need to accelerate.

Magazine: What are the production plans for the Cosmo?

Minagawa: Considering the nature of the Cosmo Sport, we do not think that there is a high demand for it at present, and for the time being, we plan to produce about 30 to 50 units per month. However, we have recently received a lot of inquiries from the export market, so depending on the demand, we can increase our production up to about 100 units per month.

Our thinking is that a sedan type is best for the mass market, and we will be exhibiting a sedan equipped with a rotary engine as part of the Cosmo series at the Tokyo Motor Show this autumn. Our plan is to launch the car next year after taking into account feedback from the Cosmo.

Fully Equipped For Service

Magazine: The price of the Cosmo Sport has been announced as 1.48 million yen, which is less expensive than we expected. How was this price decided?

Minagawa: There are many factors that go into the price, so it is impossible to give an exact explanation for why it was set at 1.48 million yen. It is true that one of the aims was to set the price lower than the selling price of the NSU Spider in Japan, which is around 1.68 million yen. As for the number 8 at the end of the price, this is said to represent Toyo Kogyo’s little trademark of good fortune… the number 8 meaning “spreading prosperity” … (laughs). Some people say that the price is a little too low, but in any case, we would like many people to drive the car and give us their opinions.

Higuchi: If I were to buy this car, where would I get it serviced?

Minagawa: Currently, it is sold at Mazda Auto stores alongside our passenger cars, and service will be done at these stores. We have already held several training sessions to ensure they are fully prepared.

Yamamoto: Since it is a new engine, we think the issue of service is a very important one. However, as you have seen, rotary engines have fewer parts to maintain and we think that servicing is actually easier than with reciprocating engines. In the beginning, we want to be as careful as possible so that we can avoid even the slightest oversight, but as the number of rotary engines in practical use increases, we would like to make it easier to service the cars anywhere in the future.

Magazine: Thank you very much for your continued support.